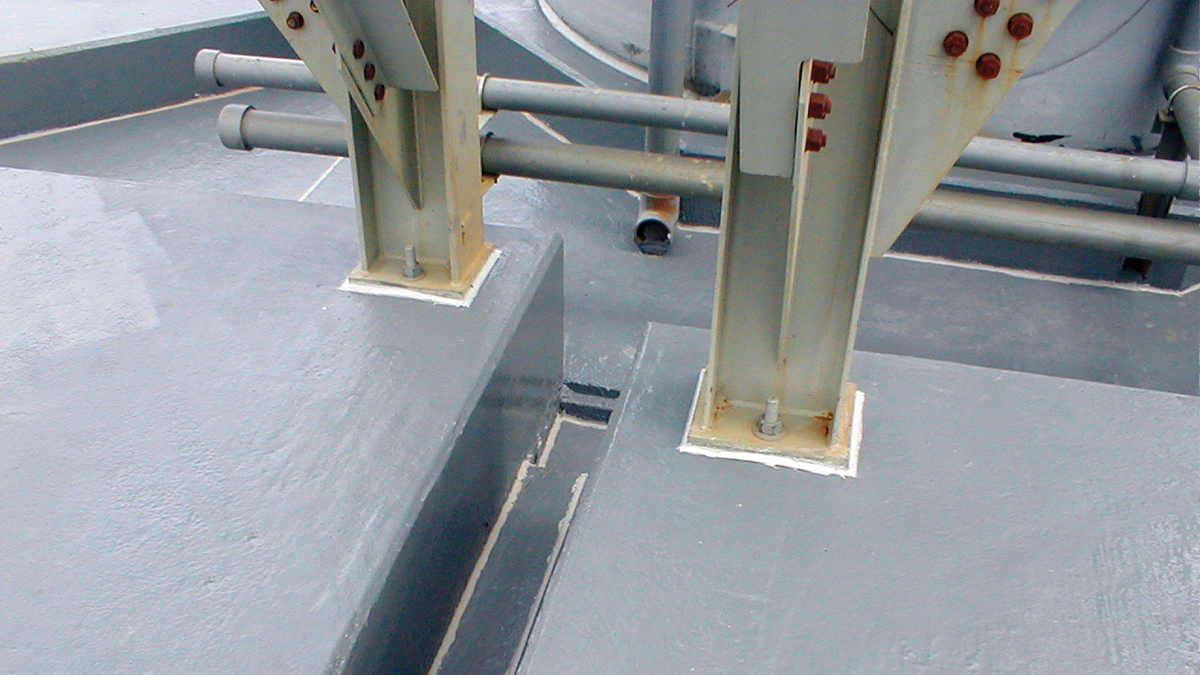

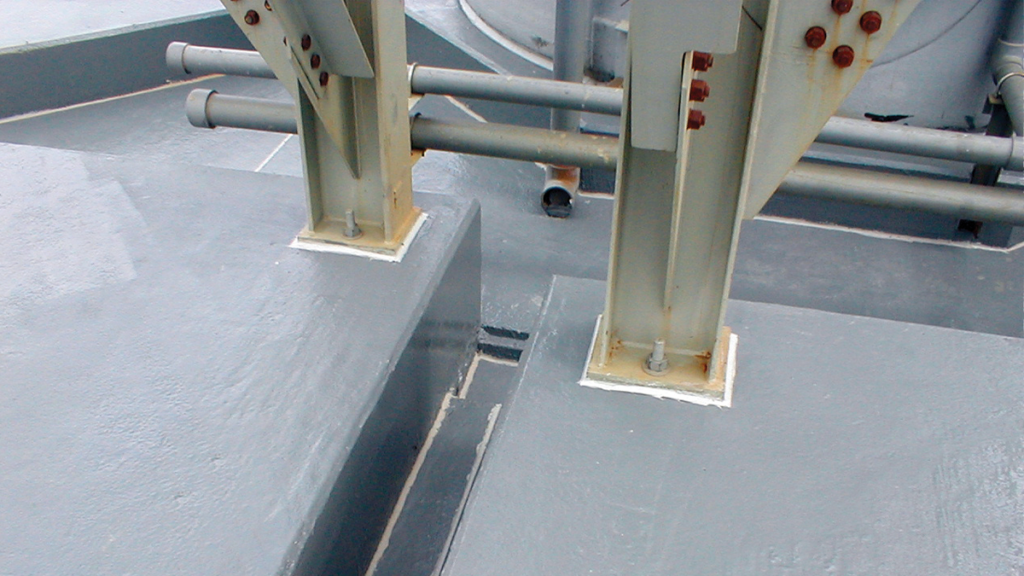

Coatings, Linings & Waterproofing

In the tough environments of industrial and power facilities, keeping concrete and steel structures strong and reliable starts with proactive maintenance. Corrosion, chemical exposure, and moisture can all take a toll, but the right coatings, linings, and waterproofing systems help stop damage before it starts. These protective solutions reduce costly repairs, safety risks, and unexpected downtime.

At PULLMAN, our local teams bring specialized expertise and industry-leading technology to every project. We identify potential risks and design customized protection strategies that deliver long-term performance. Using proven materials and advanced application techniques, we provide durable, high-performance installations that keep your facility operating efficiently.

Our protection services include:

- Expansion Joint Systems

- Chemical Grouting

- Protective Sealers, Coatings & Membranes

- Chemical Resistant Systems

- Sealant Systems

- Crack Sealing & Repair

- Drainage Systems

PULLMAN provides a wide range of specialty moisture control solutions, including:

Specialty Moisture Control & Waterproofing Expertise

PULLMAN and STRUCTURAL TECHNOLOGIES combine their unique capabilities to provide clients with both products and repair and maintenance services. PULLMAN also integrates its services with select engineering partners and STRUCTURAL TECHNOLOGIES to create turnkey, investigate – design – build solutions that provide owners with single source, cost and time-efficient projects.

Moisture Control Expertise

STRUCTURAL TECHNOLOGIES’ Solution Builders have extensive experience assisting with identifying source of water problems, helping to select or providing the right materials and aiding in the development of a constructable design solution that can be implemented properly in the field. Our team helps design solutions including:

Our Commitment to Safety & Preplanning

PULLMAN’s project management and field personnel carefully plan each moisture control project. Our crews work closely with customers to address all areas of concern during project pre-planning, including safety, constructability, budgeting, scheduling, and phasing as it relates to optimizing efficiency, and potential disruption to facility operations.

Our crews have the flexibility and manpower to match work schedules to project needs. We can complete projects under the tightest schedules or adjust and phase work to create work schedules that minimize disruption. Regardless of the conditions, our focus is on quality, on-time performance with the highest standard of safety for both our workforce and our customers.