The owner sought repairs to the structure after some of the roof’s Spanish style tiles had loosened and fallen from the building causing a safety hazard. The structure’s bricks were also damaged on the North and East facades.

The damage was found to be linked to the mortar surrounding brick being too strong, and the pressure on the bricks too high.

Project Overview

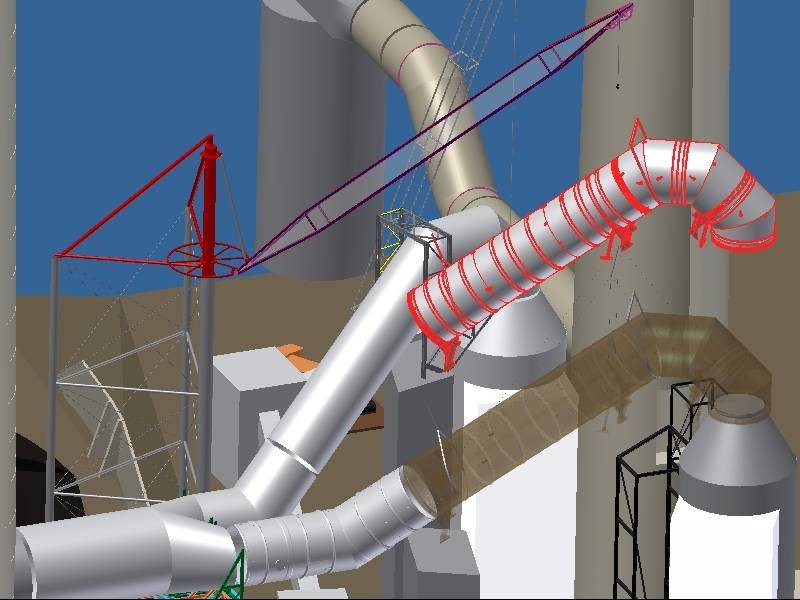

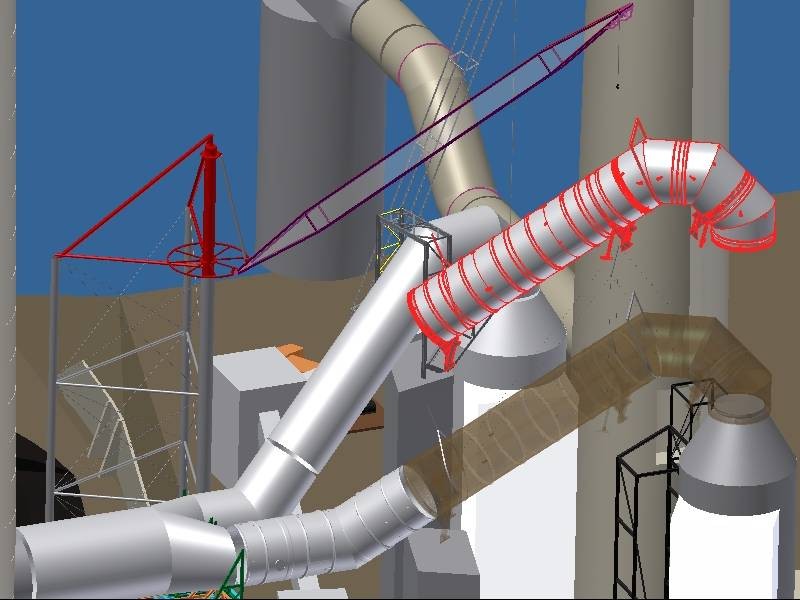

In efforts to maintain its commitment to the environment, a Midwestern power company significantly upgraded its stations by installing equipment to reduce SO2 and NOX emissions.

PULLMAN was selected by the client because our design-build capabilities and experience matched the client’s need to safely integrate the new air quality control systems with the existing plant infrastructure.

PULLMAN engineers extensively utilized building information modeling (BIM) in the preplanning process to develop detailed construction sequencing plans to meet the challenge of performing work in and around the existing systems.

The environmental project was completed on time and within budget, and continues to contribute to provide electric energy to its customers.

PROJECT INFO

- Owner: Midwest Power Company

- Location: Midwestern United States

- Specialty Contractor: PULLMAN