Inspection, Repair & Maintenance Programs for Chimneys & Stacks

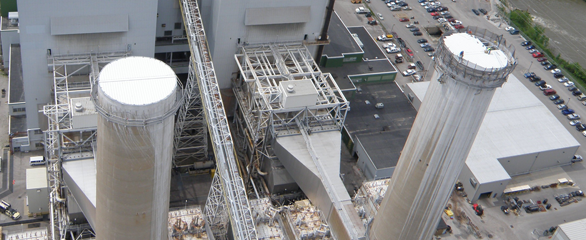

Chimneys and stacks are critical to the safe and efficient operation of power plants and industrial facilities. Over time, environmental and operational factors can cause deterioration, making regular inspection and maintenance essential to prevent safety incidents and costly unplanned downtime.

PULLMAN delivers comprehensive chimney and stack services designed to inspect, repair, and extend the service life of these vital structures.

Inspection

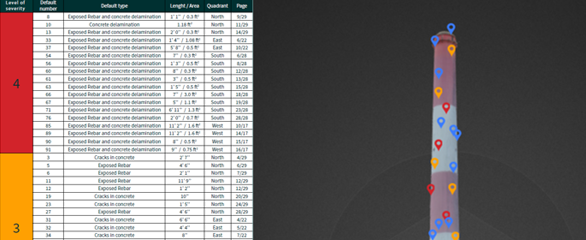

As a licensed partner of STRUCTURAL TECHNOLOGIES, PULLMAN provides customized inspection programs for industrial chimneys and stacks. Our inspections identify the root causes of deterioration, evaluate structural integrity, and recommend targeted repairs to restore performance and reliability.

Our industrial chimney inspection services include:

- Visual and drone-based inspections

- Non-destructive testing (NDT) and core sampling

- Flue liner and refractory evaluations

- Structural condition assessments and reporting

- Root cause analysis for corrosion or cracking

Regular inspections help facility operators detect issues early, schedule proactive maintenance, and prevent unexpected outages.

Repair & Maintenance Programs

Supported by advanced engineering from STRUCTURAL TECHNOLOGIES, PULLMAN delivers turnkey repair and maintenance solutions for industrial chimneys and stacks. Our teams provide both internal and external repairs to improve reliability and extend service life.

Chimney repair and maintenance capabilities include:

- Structural concrete and steel repairs

- Liner and flue replacement or rehabilitation

- Design and fabrication of custom access systems

- Installation of corrosion-resistant coatings and materials

- Chimney modernization and retrofit design for extended service life

All work is performed safely and efficiently, with minimal disruption to facility operations.

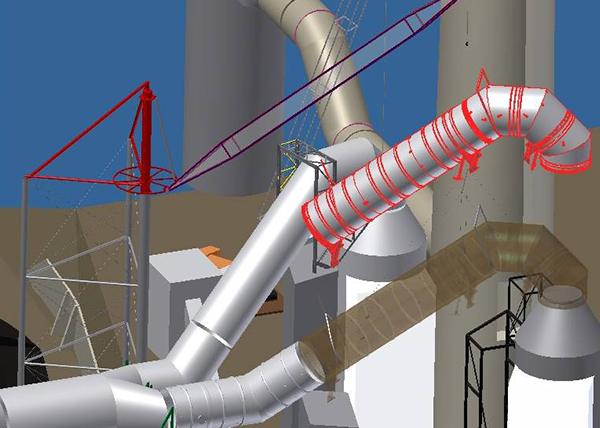

Turnkey Solutions

PULLMAN and STRUCTURAL TECHNOLOGIES offer a full-service Investigate–Design–Build (IDB) approach. From initial condition assessment to engineering and installation, clients benefit from a single-source solution for industrial chimney and stack projects. This integrated model helps operators reduce downtime, control costs, and ensure high-quality results.

Chimney Inspection Services

Repair & Maintenance Programs for Existing Chimneys

Our team designs and implements efficient solutions to fix identified problems, improve safety or extend the service life of chimney and stack components, including:

Our Commitment to Safety & Preplanning

Throughout our history, PULLMAN has been the leading designer and builder of reinforced concrete chimneys, stacks, building cores, observation towers, silos, and more. Whether you are building a new structure, or planning to modify or repair an existing one, PULLMAN’s track record and experience provides you with a reliable source for turnkey engineering and construction services.

PULLMAN’s project management and field personnel carefully preplan every project. Our crews address all areas of concern during project pre-planning, including safety, constructability, budgeting, scheduling, and phasing as it relates to optimizing efficiency and potential disruption to ongoing operations.

PULLMAN crews have the manpower to complete projects under the tightest schedules or adjust and phase work to create work schedules that minimize disruption.